|

TRC's emphasis on quality has always used the most

effective

elements of Lean

Manufacturing.

5S, Kaizen

events and

Kanban are just

a few

examples. Our

most recent

addition to our

Lean tool box

has been the

addition of Built In Quality-BIQ for short

BIQ drives home best in class quality by being proactive

rather than

reactive. The

basic principle

of BIQ is to

stop the flow of

defects as close

to their source

as possible;

with no defects

leaving the

production environment.

This is

accomplished via

use of "gates"

and visually

driven

checklists at

critical areas

of the

remanufacturing

processes.

Resources are

then deployed to

eliminate the

cause of the

defect

using proven

lean

technologies.

Early benefits

to the roll out

of BIQ in our

remanufacturing

facilities has

been a reduction

in warranty

claims, improved

efficiency as a

result of

reduced rework

and improved

working conditions

for our

technicians.

|

-

Stop the

defect

-

Get a

detailed

description

of the

defect

-

Pareto the

defects to

target the

most

problematic

-

Share defect

detail with

the offender

-

Conduct RCCA

(Root Cause

Corrective

Action)

-

Drive

feedback to

all

technicians

-

Drive RCCA

into

standard

work

documents

-

Repeat the

process

|

|

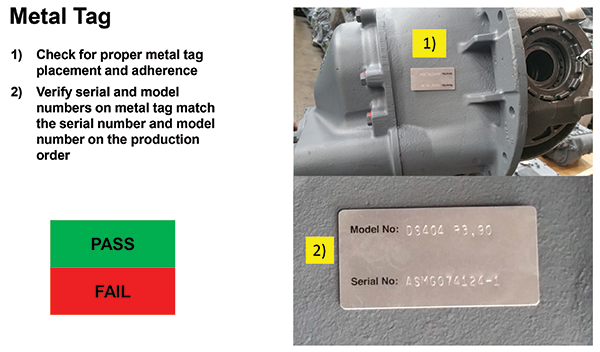

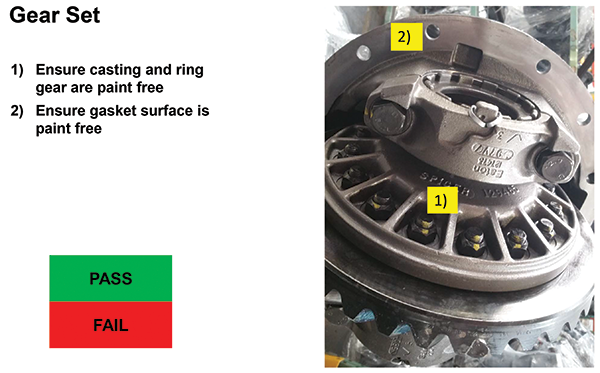

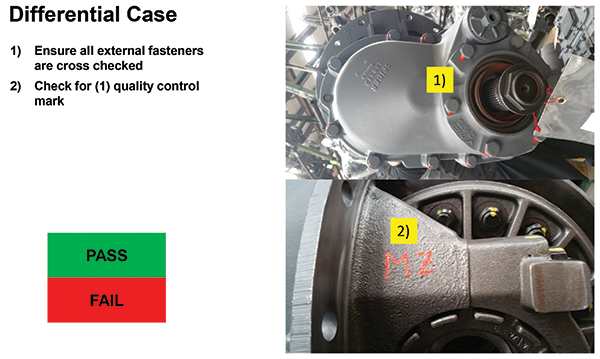

BIQ Checklists

* Details of key components require a Pass or Fail

* "Fails" are returned to the offender for immediate

correction.

|

|

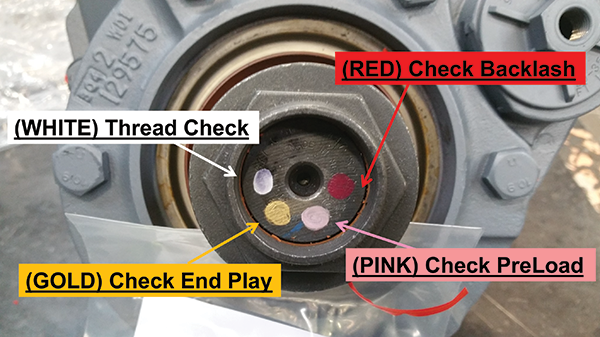

Process relies on IPV (In Process Validation)

* A technician's "thumbs up" to indicate the processes were

completed

accurately

|

|

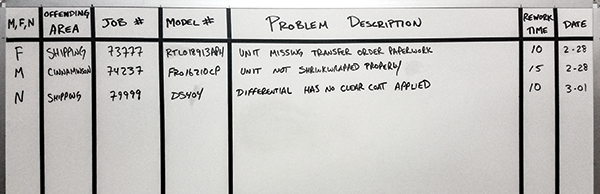

Whiteboard Documentation

* "Live Feed" concept * Open communication * Guarantees

documentation to

improve standard

work

|

|

Stopping The

Flow Of Defects

Guarantees Customer

Satisfaction

|

|

|